WebBased Monitoring System for Power Quality Analyzer

Web Based Online Data Logging System for Power Quality is an essential service many utilities perform for their industrial and larger commercial customers. Because of the technology and software now available, this monitoring is a highly effective tool. Not only can a system provide information about the quality of the power and the causes of power system disturbances, but it can also identify problem conditions throughout the system before they cause widespread customer concerns, equipment malfunctions, and even equipment failures. Power quality problems are not necessarily limited to the power supply system. Many surveys have shown that the majority of problems are localized within customer facilities. Given this fact, Online Data Logging System is a service opportunity that can be applied to the entire utility customer base.

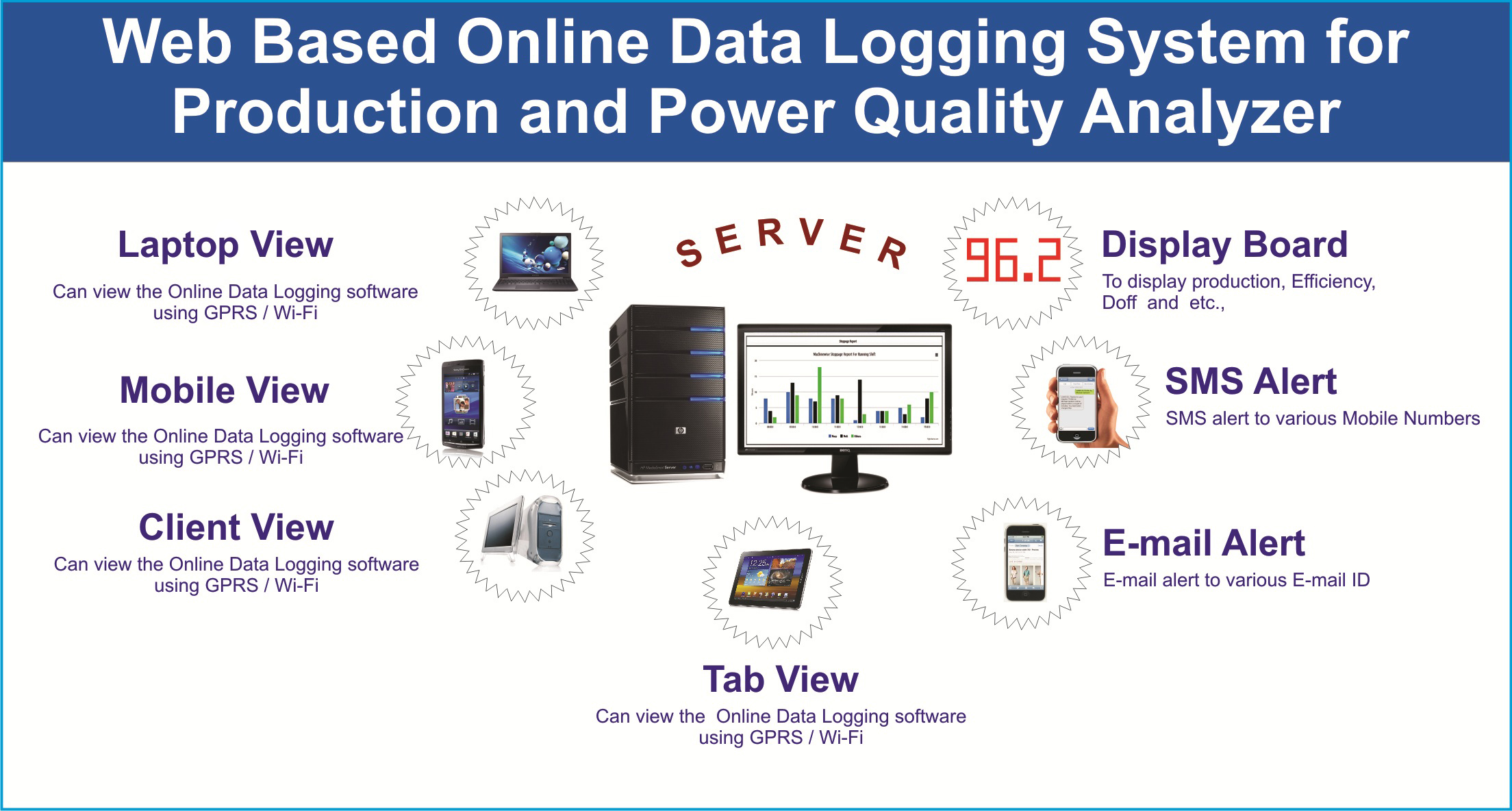

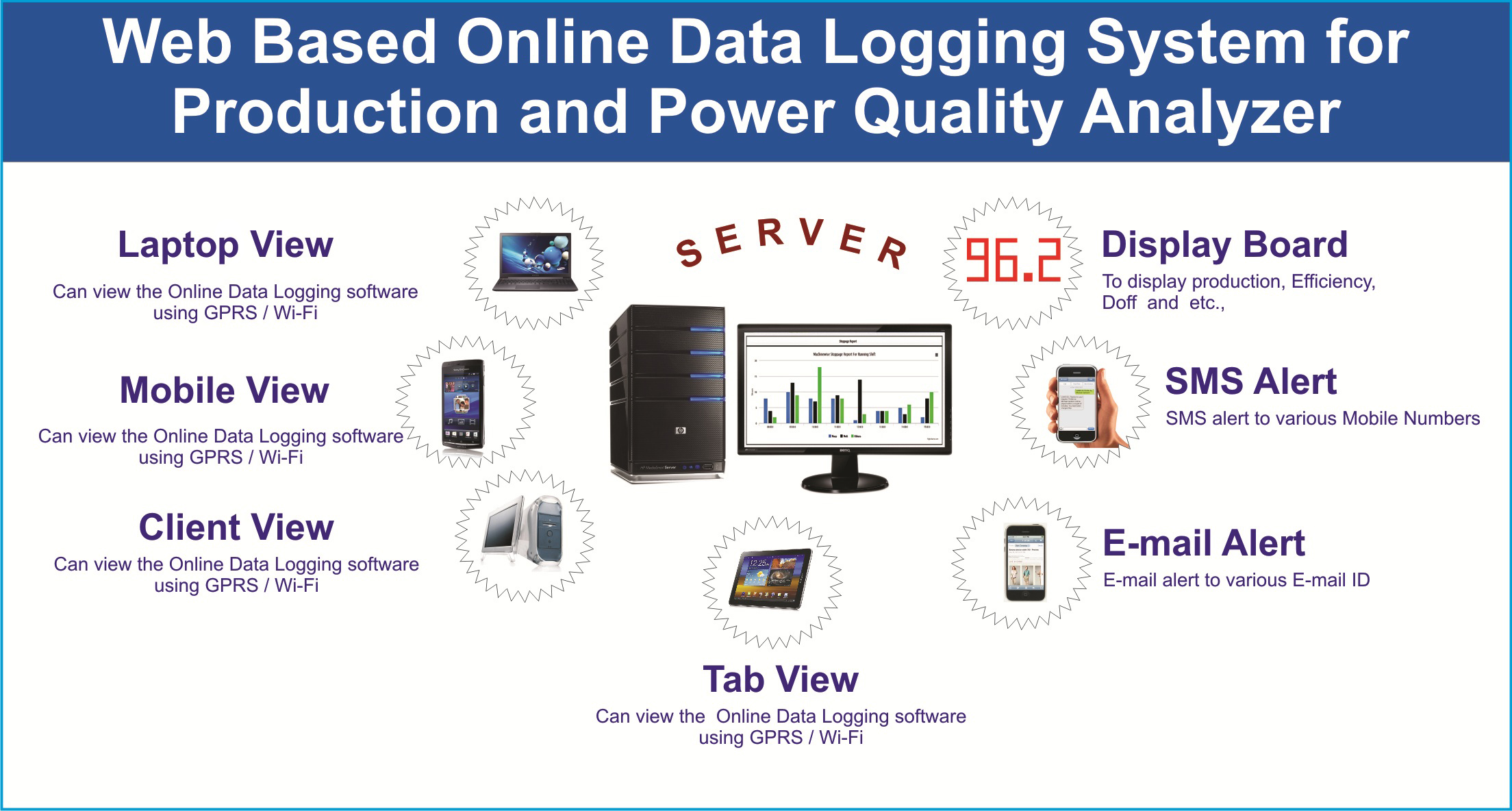

Essential requirements for a successful monitoring system include extensive data logger device, processing capabilities, easily understood reports, and universal sharing of information both within the utility and with the customer’s facilities personnel.

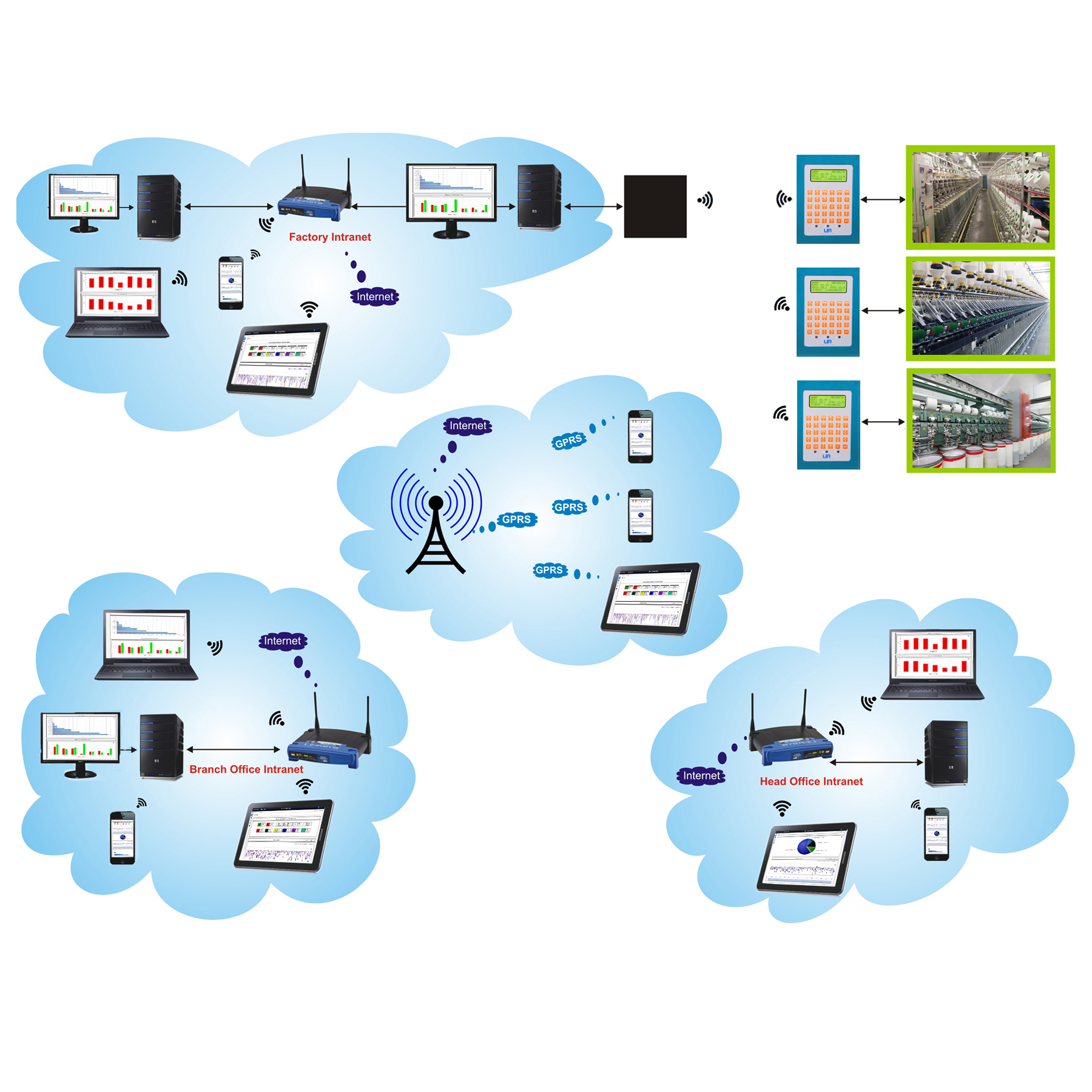

Utilizing state-of-the-art monitoring technology and software, many utilities are able to offer their customers the benefits of power monitoring through a low-cost monitoring service. Using recently developed software for the World Wide Web, utilities are able to give customers access to power quality monitoring data via the Internet. In fact, several utilities offer this service to their largest customers as a value-added service. Using the Internet based software to display monitoring data allows utility engineers and customers to gain access to data with a minimal amount of system configuration, engineering, or training on specialized software packages. Any Internet browser can be employed to view the monitoring data on a password-protected site. The monitors are remotely downloaded via central servers maintained by the utility or third party consulting firms, with the data and analysis made available over the Internet. Alarming features are available that allow almost instantaneous notification of power quality disturbances via alphanumeric pages, faxes, or e-mails.

View more

Why WMS 802.MS?

Using Data logger, we can identify the weak areas and can improve the same area immediately. The earliest form of recording data involved manually taking measurements, recording them to a written log, and plotting them on graph paper. In the late 19th century, this process was automated with the use of strip chart recorders that mechanically recorded measurements onto paper. Strip chart recorders were a great leap over manual recording but still had drawbacks.

Traditional data loggers are stand-alone box instruments that measure signals, convert them to digital data, and store the data to internal memory. Data must be physically transferred to a PC for visualization, analysis, and permanent storage.

PC-based data loggers, on the other hand, are a combination of a data acquisition device and a PC. Because the PC is actually a part of the system, the data logger can take advantage of the ever-increasing performance of the PC processor, hard drive, display, and I/O bus.

View more

Advantage of WMS 802.MS.

This presents the following advantages over traditional stand-alone WMS 802.MS:

- Real-time visualization

- Inline analysis

- User-defined functionality

- Terabytes of data storage

- Network connectivity

Real-Time Visualization

With a traditional stand-alone data logger, you must first record the data and then manually transfer it to a PC before you can import it into a spreadsheet program or other tool to graph and visualize the data.

Because a PC-based data logger is always connected to the PC, live measurements are displayed on the PC monitor in real time and you can see results instantly. You can use programming environments, such as Web Based Software, to build custom user interfaces for controlling your measurement device and displaying the results. Creating a user interface with Web Based Software is as simple as dragging and dropping controls and graphs on the user interface.

Inline Analysis

Data analysis with a traditional stand-alone data logger is typically performed offline only after the data has been transferred to the PC.

Using a PC-based data logger, you can take advantage of multicore processors and increasingly available RAM in the PC to perform signal processing and analysis on your data as you acquire it. Web Based Software includes many common math and signal processing functions that use configuration wizards and make it easy to add analysis to your measurements.

User-Defined Functionality

With a traditional stand-alone data logger, you are generally limited to hardware and software functionality defined by the vendor. These functions are good for accomplishing general-purpose tasks, but they may not help you meet your unique application requirements. For example, you may want to log data only under certain conditions or generate custom alarms that aren't built into the data logger.

PC-based data loggers are software-defined instruments. This means the functionality of the device is defined by the software, and you can customize the software to meet your specific application needs. Using Web Based Software, you can easily build functionality for custom alarms, logging conditions, report generation, and signal analysis. You can log data to virtually any file format for importing into other tools and sharing data with others.

Terabytes of Data Storage

Data storage is an important component of a data logger. You can log only as much data as you can store in your data logger. Traditional stand-alone data loggers are limited by the amount of memory built into the device.

Because the PC is actually a part of a PC-based data logger, you are limited only by the amount of hard drive space on the PC. Today, it's not uncommon to find a PC hard drive with terabyte capacity that provides ample space for your current measurements as well as permanent storage space.

Network Connectivity

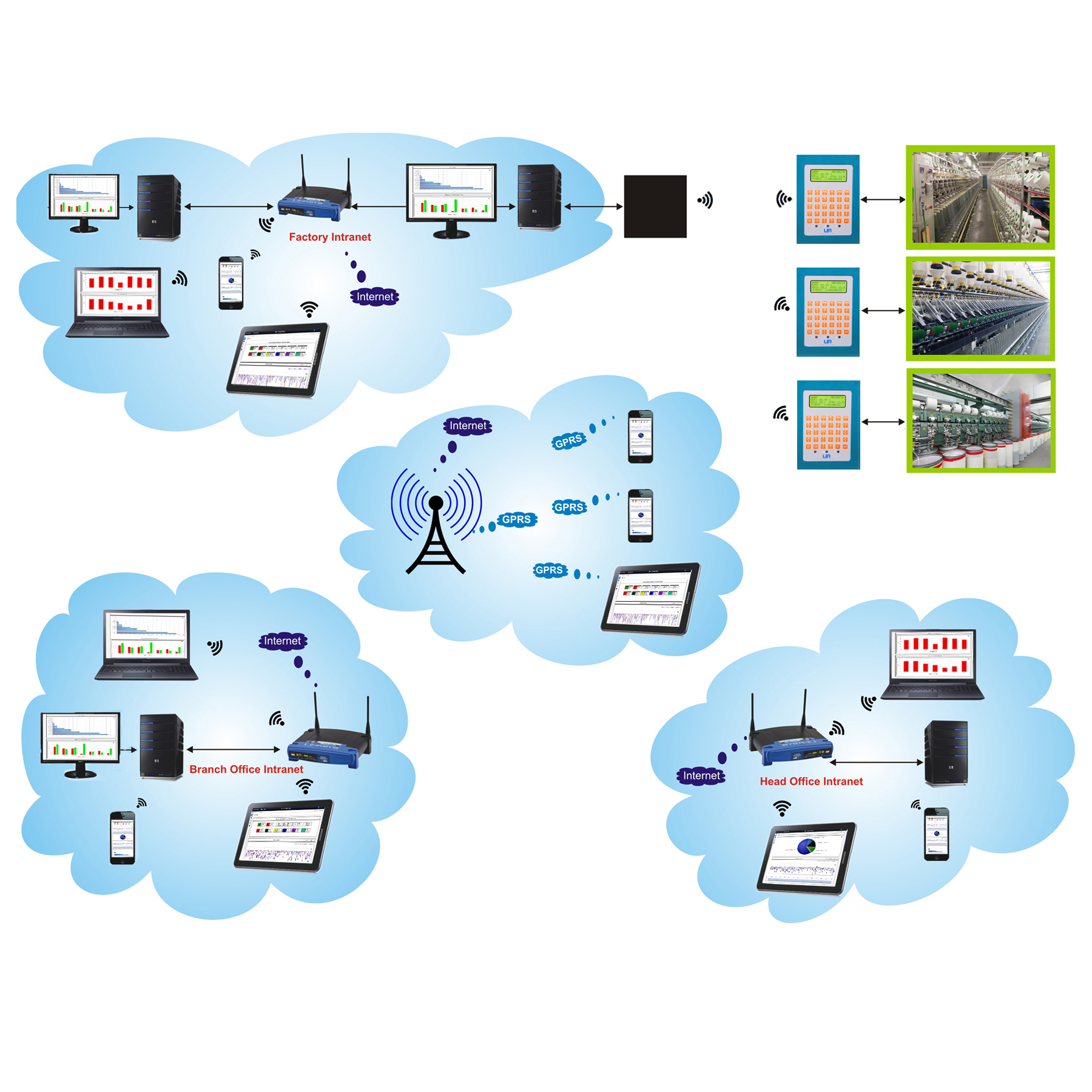

For applications that require long-term monitoring over days or weeks, you may have difficulty continually checking results. Remote monitoring is useful because you can see results from a remote location. Using a PC-based data logger, you can take advantage of the PC's network connectivity to transmit results over a network for remote viewing. With Web Based Software, you can create custom alarm conditions that send e-mails or even design a Web service that you can visualize over a Web-based application.

View more

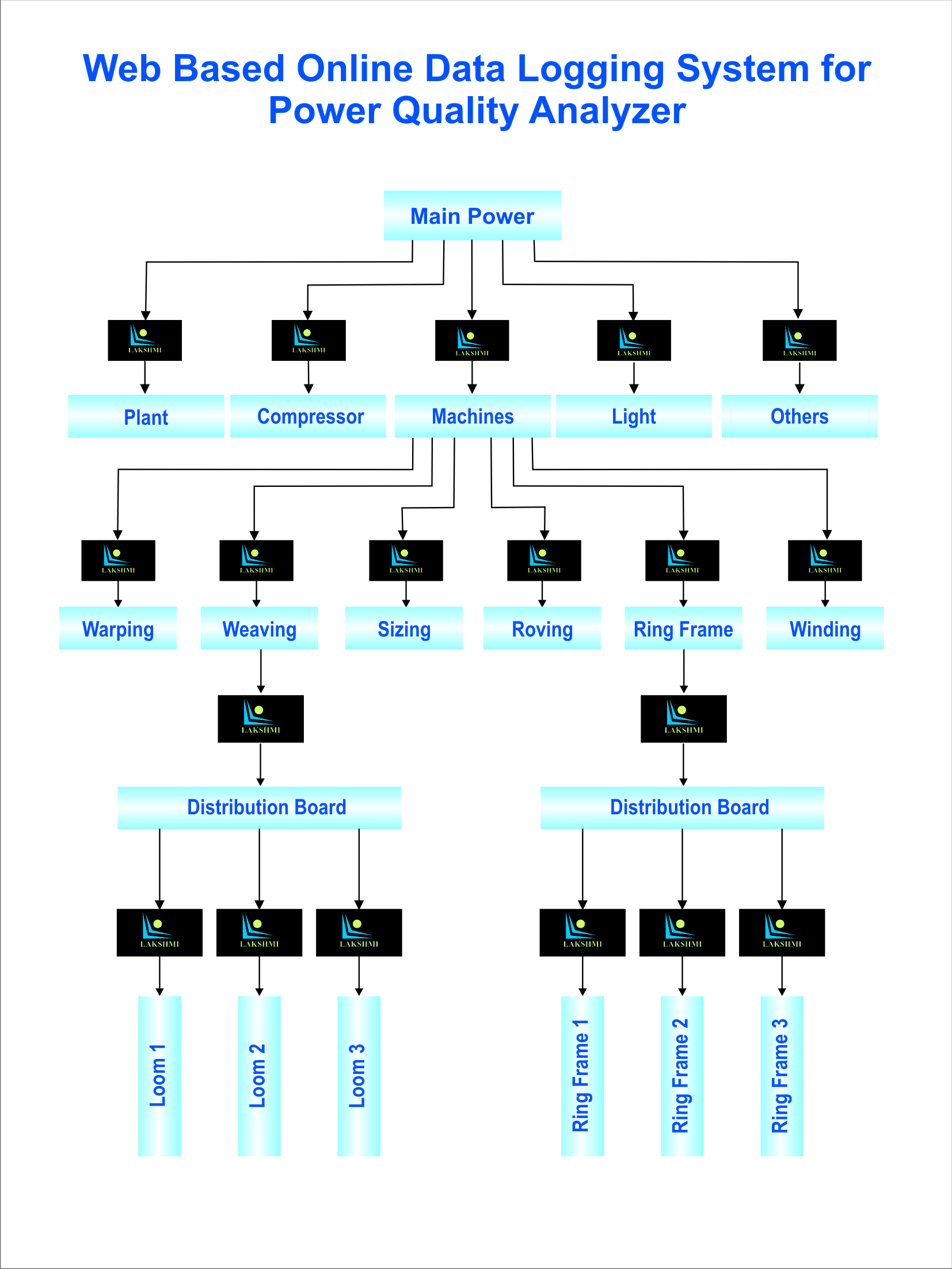

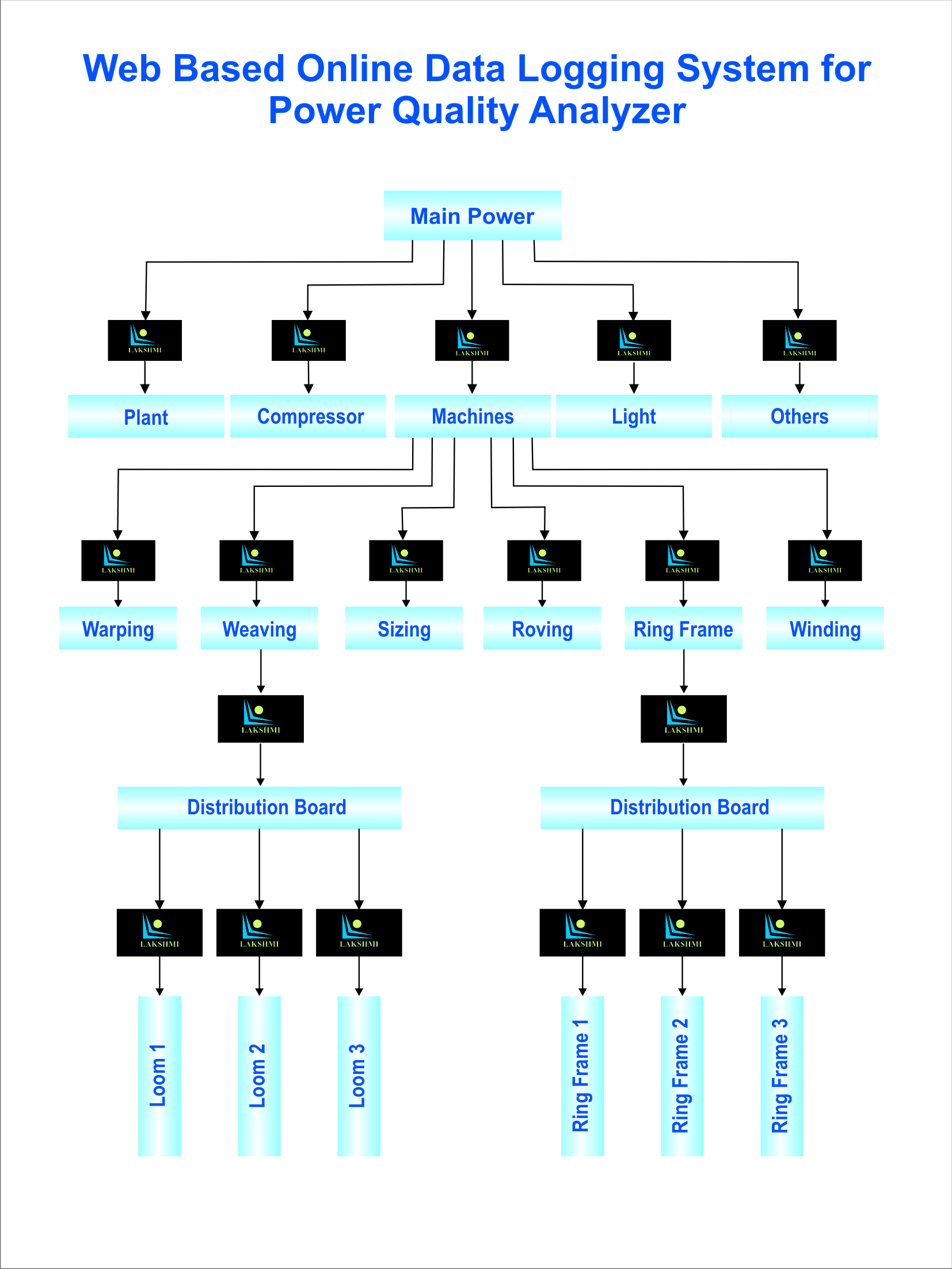

Block Diagram for Power Quality Analyzer

Here are some more reasons for

WebBased Monitoring System for Power Quality Analyzer

- Identify power quality problems

- You can increase the life of IT or highly advanced equipment

- Protect motors from damaging currents and surges

- Prevent transformers and conductors from overheating

- Locate and identify equipment malfunction, BEFORE it malfunctions

Why install a Power Quality WMS 802.MS?

There are many benefits to installing a Power Quality Data Logger system — some of which strongly interrelate with each other. A properly designed and installed Data Logger system offers a deeper understanding of the operational parameters of the facility's electrical system. A close appraisal of the data generated by a Data Logger system can reveal a variety of overt and subtle opportunities, including:

Environmental — A better knowledge of how energy is used within a facility allows you to identify an array of prospects to improve efficiency, minimize waste, and reduce energy consumption, thereby allowing the facility to be a better steward of its allotted natural resources.

Reliability — Assessment of data from the Data Logging system can reveal existing or imminent issues that can adversely affect the operation and product within a facility. Historical data from power monitoring systems can help locate and correct both acute and chronic problems, resulting in increased productivity.

Maintenance — Data trends can forecast and notify the appropriate people when discrete equipment parameters may be exceeded, allowing you to plan ahead instead of facing an unscheduled shutdown.

Safety — Data Logging systems can limit the exposure of personnel to potentially hazardous electrical environments by providing remote status and operational parameters of equipment within hazardous areas. Some Data Logging devices also offer a variety of additional parameters (temperature, pressure, flow rate, vibration, status indicators, etc.) through the use of transducers.

Financial — Each benefit discussed above either directly or indirectly influences a business's bottom line. In most cases, the monetary impact from even one or two benefits can quickly justify the purchase and installation of a power monitoring system.

Additional advantages offered by power monitoring systems may include features such as accurate evaluations of spare electrical system capacity, billing allocation and validation, or optimum placement of mitigation devices. Once you decide if a power monitoring system makes sense in your particular situation, the next step is narrowing the field of choices.

Block Diagram

View more

View more

WMS 802.MS System - Hardware

The Data Logging system hardware consists of Microcontroller, Voltage Sensing Modules,Current Transformer and etc. Captured data(Phase Voltages,Line Voltages, Line Currents,Frequency,Power Factor, Power Consumed) can be collected via voltage sensing modules and current transformers. Collected data will be transmitted with a time interval to the central server for the further process.

The monitoring instruments are used to gather the required measurements. Every Minute, the Master station “call” and download the monitoring instruments. Master station be responsible for monitoring instruments and store the monitoring data. A multi-gigabyte drive is used to store the power quality data. With this drive, has the capability of storing approximately two years worth of data on-line.

View more

WMS 802.MS Device Features

- Rugged, Dust & Oil proof Cabinet

- Phase and Line Voltage Reading Sensor.

- In Build Current Transformer Coil.

- Less Maintenance.

WMS 802.MS System - Software

The heart of any monitoring system is the software that drives the system. Without the proper software, gathering, analyzing, and reporting the monitoring data would be a tedious task. The following sections describe the software used to communicate with the monitoring instruments, analyze the monitoring data, and report the data to the user via the Internet.

Web Based Online Data Logging Software was developed for use on the intranet to enable engineers and technicians throughout the company to view and analyze power quality data. The power quality group was concerned about the security of the data files and decided to seek a way to give users read-only access to the databases. In addition,By relying on Internet browsers and hyperlinks, Software allows users to have read-only access to the power quality data and requires no extensive training. In addition, its extensive online help makes the software easier to use.

Software allows the user to plot trends of the RMS voltages and currents. These trends can be selected for one day, one week, one month, one year, or any arbitrary period of time. The trend data displays the minimum, maximum, and average RMS values of all cycles. It is a convenient method to summarize the power quality of a site over a given period of time. This plot is also useful to show voltage regulation and load change patterns.

All of this allows the users to view power quality data without having to install a large amount of software on their computers. All of the work is done on the Web server, so the user only needs a standard Web browser to view the data.

View more

Features

How it Works

Web or intranet server to make power quality information and data available to engineers, customers, and representatives who need quick access to that data. In order to access the data, the user needs to know the address (URL) of the power quality data site(s), have a Web browser such as Netscape Navigator or Microsoft Internet Explorer, and have the required passwords to enter the system. The request from the user and sends an HTML file back to the user, which is viewed with a Web browser.

The user may view a RMS report, which may contain an event list, histogram table, curve, and/or 3D Histogram. A time range filter is applied to the request, and the report is sent back to the user.

The date and time ranges are entered, the monitoring site(s) is selected, and the desired power quality information is selected. The request is sent to the back-end server, and the results are displayed.

What Can be Viewed?

The software allows viewing of all data that has been previously downloaded from the monitoring instruments using the monitor’s proprietary software and stored on the network server. For example, if an engineer is looking for events that occurred during the previous week, a password is entered, sites of interest are selected, and the date and time of interest are entered. An event list is returned, and the user may view each event in more detail. The events are viewed individually by phase.

The disturbance detail feature allows the user to view all aspects of an event. Cycle-by-cycle RMS summaries and waveform captures can be used for event analysis and troubleshooting. Voltages and or currents can be displayed. Data such as this is now immediately available to such groups as control room operators, system protection engineers, customer service representatives, and any other employee connected to the Con Edison network. Access is available across a range of operating systems, including Windows, OS2 and UNIX.

View more

View more

View more